We know that transistors and tubes are necessary to produce the sound, but did you ever wonder about some of the other parts and if they contribute to the sound?

I have wondered, and I decided to explore.

Capacitors are one of these audio parts that are extremely important in electronic circuits.

Below is an extensive explanation of what capacitors are, how they work, how they are manufactured, and how they affect the sound we listen to.

As always, I acknowledge the assistance of those who help me with such projects. Dr. David Rich is a walking encyclopedia, particularly because he has a Ph.D. in electrical engineering.

Special Considerations for Audio Capacitors: Audio capacitors are designed to minimize noise, distortion, and signal loss. Temperature Stability: Materials are chosen for their stable performance across a range of temperatures. Precision: Tight tolerances (e.g., ±1% or better) ensure accurate audio reproduction. Note that 1% tolerance capacitors are available only in film caps and are expensive. Typical tolerances will be much larger. In the case of power supply and amplifier circuits, tolerance is not much of a concern. The RIAA EQ is a big concern, as it would be for a passive crossover network, requiring novel circuit solutions to achieve very small errors from the RIAA standard.

This is why we are seeing more active speakers (they have built-in power amplifiers) appearing on the market. Some have DSP in front of the amplifier section which eliminates the need for capacitors, inductors, and resistors that are in a passive crossover network.

The large caps with high voltage ratings in a passive speaker are almost always electrolytic due to the high cost of large-value film capacitors. High-order crossover networks are more sensitive to capacitor tolerance than low-order networks, compounding design issues with capacitor selection within the allocated bill of materials cost set for a given passive speaker crossover network.

If active speakers have capacitors in the crossover, the voltages are small (5 VRMS max), and currents are in the micro amp ranges. In many cases, the active crossover can be all film caps. In passive speakers, film caps are really expensive. The price increases significantly with size so that a tweeter crossover might use film caps, but the woofer uses electrolytic caps.

There are also inductors in speakers. Iron-core inductors have similar distortion issues to electrolytic capacitors. Again, you may see an air-core inductor in the tweeter path, but an iron-core will be in the woofer. Tower speakers costing under $1,000 may have all iron-core and electrolytic caps. You are well into five figures for all film caps and air-core inductors.

Capacitance and inductance in speaker cables are inaudible compared to the distortion in the passive crossover. The exception is speaker cables designed for sound with high inductance to roll off the high end and high capacitance to make the amplifier unhappy. Active speakers use RCA cables, not speaker cables.

So, what is a capacitor?

A capacitor stores electrical energy in the form of electrons (bazillions of electrons) up to a maximum specified voltage and amount (specified in fractions of a Farad). It helps to amplify, manage, and filter audio signals, reduce noise, and stabilize voltage.

How a Capacitor Works:

An audio capacitor works by storing and releasing electrical energy to control the flow of signals in audio circuits. Its primary purpose is to improve sound quality by filtering, coupling, and decoupling signals, and it plays a vital role in shaping the audio output. Here’s a breakdown of its working principles and functions:

- Basic Working Principle

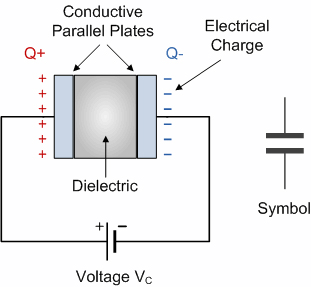

A capacitor consists of two conductive plates separated by a dielectric material (an insulator). When voltage is applied:

- One plate (one of the metal windings) accumulates a positive charge, and the other (the second metal winding) accumulates a negative charge, creating an electric field in the dielectric.

- The capacitor resists sudden changes in voltage by storing energy in the electric field and releasing it when the circuit requires it.

- The electric field is created in the dielectric.

* Image copyright https://www.electronics-tutorials.ws/capacitor/cap_9.html/comment-page-2

- Functions in Audio Circuits

- Coupling

- Capacitors are often used to connect (or couple) different stages of an audio circuit while blocking DC signals.

- How it works:

- The capacitor passes AC signals (the audio signals) while blocking DC components, ensuring only the desired audio frequency range moves through the circuit.

- This prevents DC offsets from distorting the audio signal or damaging subsequent components.

- Decoupling

- Capacitors are used to smooth out voltage fluctuations and filter noise from power supplies.

- How it works:

- The capacitor acts as a temporary energy reservoir, supplying power during dips in voltage and absorbing excess energy during surges.

- This reduces hum and noise in the audio signal caused by power supply variations.

- Filtering

- In crossover networks for speakers, capacitors filter specific frequency ranges to send to different drivers (e.g., woofers, tweeters).

- How it works:

- High-pass filters: Allow high frequencies to pass while blocking low frequencies.

- Low-pass filters: Allow low frequencies to pass while blocking high frequencies.

- Timing and Signal Shaping

- Capacitors can be part of circuits that shape and control audio signals, such as equalizers or tone controls.

- How it works:

- The capacitor’s ability to charge and discharge at specific rates helps in creating time delays or adjusting frequency responses.

- Performance Characteristics

Secrets Sponsor

Key Attributes That Impact Audio Quality:

- Capacitance: Determines how much charge the capacitor can store and its ability to pass or block certain frequencies.

- ESR (Equivalent Series Resistance): Affects energy loss within the capacitor. Low ESR capacitors are preferred for high-fidelity audio.

- Frequency Response: High-quality audio capacitors maintain consistent performance across a wide frequency range.

- Dielectric Material: Materials like polypropylene or polyester are often used for audio capacitors due to their low loss and stability.

- Voltage Coefficient: There is a phenomenon called capacitor voltage coefficient distortion. This is caused by changes in the capacitance depending on the voltage that is applied to the capacitor, which results in distortion. This is particularly a problem with AC circuits that are conducting music signals because it causes the time constant of the circuit to move with the amplitude difference modulating the time constant of the RC network. Some types of ceramic capacitors (with high dielectric constants) are particularly prone to this problem since the voltage coefficient is large. Capacitors in integrated circuits can have large voltage coefficients dependent on if extra process steps are introduced which adds to the wafers cost.

- Example Applications in Audio Systems

- Amplifiers: Audio capacitors filter out unwanted frequencies and stabilize voltage supplies.

- Crossovers: Separate high, mid, and low frequencies for distribution to specific drivers in speakers.

- Noise Reduction: Smooth power supply variations to prevent hum and hiss in audio systems.

- Tone Controls: Shape and adjust audio frequencies for bass, midrange, and treble settings.

An audio capacitor functions as a vital component in audio circuits, enhancing sound quality by ensuring clean signal transmission, reducing noise, and accurately shaping frequency responses. Its performance directly influences the clarity, detail, and overall fidelity of the audio output.

An audio capacitor does not store voltage or current directly. Instead, it stores electric energy in the form of an electric field between its plates. However, voltage and current are involved in the capacitor’s operation, and their relationship is fundamental to how it works. Here’s a detailed explanation:

Energy Storage

- A capacitor stores energy (E) as an electric field between its plates, with the amount given by: E=1/2•CV2

- C: Capacitance (in farads)

- V: Voltage across the capacitor (in volts)

- The energy is not stored as voltage or current but as the physical separation of charges on the plates. The voltage across the capacitor is a result of the stored energy.

Voltage Across the Capacitor

- Voltage Storage:

- The voltage across the plates builds up as the capacitor charges and diminishes as it discharges.

- The capacitor maintains a voltage proportional to the amount of charge stored: Q=CV.

- Q: Charge (in coulombs)

- V: Voltage (in volts)

- C: Capacitance (in farads)

- This stored voltage affects how the capacitor interacts with the circuit.

A Coulomb (symbol: C) is the SI (International System of Units) unit of electric charge. It quantifies the amount of electric charge carried by a current over a specific period of time.

Definition:

One coulomb is defined as the amount of electric charge that flows through a conductor when a current of 1 ampere (A) flows for 1 second (s):

1C=1A⋅1s

Physical Interpretation:

- A charge of 1 coulomb corresponds to approximately 6.242×1018 elementary charges (such as electrons or protons), and the charge of one electron is about −1.602×10−19 C.

- For perspective, this is a large amount of charge compared to what we typically encounter in everyday devices.

Key Relationships:

- Current and Charge:

- The relationship between current I, charge Q, and time t is Q=I⋅t

- Here, Q is measured in coulombs, I in amperes, and t in seconds.

- Capacitance and Voltage:

- In a capacitor, the charge Q is related to the capacitance C and voltage V: Q=C⋅V

- Examples:

- A current of 2 A flowing for 3 seconds delivers: Q=I⋅t=2⋅3=6C. (6 coulombs)

- If a capacitor with C=10μF (microfarads) is charged to V=5 V, the stored charge is: Q=C⋅V=10×10−6 5=50×10−6 C = 50 µC (micro-coulombs)

- Everyday Contexts:

- A typical smartphone battery stores charge in the range of thousands of coulombs.

- A lightning bolt transfers a large number of coulombs, making it a much larger-scale phenomenon compared to typical electronic applications.

In summary, the coulomb is a fundamental unit in electromagnetism, providing a measure of how much electric charge is present in a system or transferred during a process.

Current Through the Capacitor

- Current Flow:

- Capacitors do not allow a direct current (DC) to flow through them because of the insulating dielectric material between the plates.

- However, when the voltage across the capacitor changes (as in AC signals), current flows into or out of the capacitor as it charges and discharges.

- The current through the capacitor (I) is related to the rate of change of voltage (dV/dt)

I=C•dV/dt

- Faster changes in voltage cause higher current flow.

The formula dV/dt represents the rate of change of a quantity V with respect to time t. It is a derivative in calculus, often used to describe how a variable V changes over time.

The formula I=C•dV/dt is a key equation in electrical engineering and physics. It describes the current I through a capacitor in terms of its capacitance C and the rate of change of voltage dV/dt across the capacitor.

Components of the Formula:

- I (Current):

- Represents the electric current flowing through the capacitor, measured in amperes (A).

- Current is proportional to how quickly the voltage across the capacitor changes.

- C (Capacitance):

- The capacitance of the capacitor, measured in farads (F), quantifies the ability of the capacitor to store charge.

- A larger capacitance means the capacitor can store more charge for a given voltage.

- dV/dt (Rate of Change of Voltage):

- The derivative of voltage V with respect to time t, measured in volts per second (V/s).

- Indicates how rapidly the voltage across the capacitor changes over time.

Physical Meaning:

This equation comes from the relationship between charge Q, capacitance C, and voltage V.

Breakdown of the Notation:

- V: A variable that depends on time (e.g., volume, velocity, voltage).

- t: Time.

- dV/dt: The derivative operator, indicating a rate of change with respect to time.

Role in Audio Applications

- Voltage Behavior:

- The capacitor blocks DC voltage (steady-state voltage) while allowing AC voltage (audio signals) to pass.

- This ensures that only the intended audio signal is transmitted in coupling or filtering applications.

- Current Flow:

- In audio circuits, the capacitor responds to changes in the audio signal (AC voltage), allowing the signal current to flow in and out dynamically.

- The capacitor’s response to signal frequency impacts the circuit’s performance (e.g., filtering specific frequencies).

Key Points

- Voltage Storage: The voltage across the capacitor reflects the amount of energy stored but is not a direct storage mechanism for voltage itself.

- Current: Current flows in response to voltage changes, but the capacitor does not store current.

- Energy Storage: The actual storage in the capacitor is the separation of electrical charges, creating an electric field.

In summary, while voltage and current are integral to a capacitor’s operation in an audio circuit, what it fundamentally stores is electric energy, not voltage or current directly.

Current Through the Capacitor

- Current Flow:

- Capacitors do not allow a direct current (DC) to flow through them because of the insulating dielectric material between the plates.

- However, when the voltage across the capacitor changes (as in AC signals), current flows into or out of the capacitor as it charges and discharges.

- The current through the capacitor (I) is related to the rate of change of voltage (dV/dt).

Role in Audio Applications

- Voltage Behavior:

- The capacitor blocks DC voltage (steady-state voltage) while allowing AC voltage (audio signals) to pass.

- This ensures that only the intended audio signal is transmitted in coupling or filtering applications.

- Current Flow:

- In audio circuits, the capacitor responds to changes in the audio signal (AC voltage), allowing the signal current to flow in and out dynamically.

- The capacitor’s response to signal frequency impacts the circuit’s performance (e.g., filtering specific frequencies).

Key Points

- Voltage Storage: The voltage across the capacitor reflects the amount of energy stored but is not a direct storage mechanism for voltage itself.

- Current: Current flows in response to voltage changes, but the capacitor does not store current.

- Energy Storage: The actual storage in the capacitor is the separation of electrical charges, creating an electric field.

In summary, while voltage and current are integral to a capacitor’s operation in an audio circuit, what it fundamentally stores is electric energy, not voltage or current directly. An ideal capacitor does not dissipate power when presented with an AC signal because the current and voltage are 90 degrees out of phase.

Capacitors and ESR:

ESR stands for Equivalent Series Resistance, a parameter of electronic components, especially capacitors. It represents the internal resistance in series with the ideal capacitance of a component.

What is ESR?

- Capacitors are not perfect; in addition to their ideal capacitance, they have parasitic properties like resistance, inductance, and leakage. ESR is the resistive part of these imperfections.

- ESR is measured in ohms (Ω) and varies based on the type of capacitor, frequency, temperature, and aging.

Why is ESR Bad?

High ESR can lead to several problems in electronic circuits, especially in power supplies, audio systems, and high-frequency applications:

- Power Losses

- The resistance in ESR causes power dissipation as heat when current flows through the capacitor.

- In high-current applications, this can lead to significant energy loss and overheating.

- Reduced Efficiency

- In power supplies, ESR increases ripple voltage and decreases filtering efficiency.

- High ESR capacitors cannot effectively smooth out voltage fluctuations, leading to unstable operation.

- Heating and Component Failure

- Power dissipation due to ESR generates heat, which accelerates aging and degrades the capacitor.

- Over time, this can lead to leakage, reduced capacitance, and eventual failure.

- Audio Quality Issues

- In audio circuits, high ESR can cause distortion, noise, or degraded frequency response, especially in coupling and decoupling capacitors.

- Instability in High-Frequency Circuits

- ESR affects the performance of high-frequency circuits like oscillators and RF circuits by altering impedance and introducing losses.

How to Mitigate ESR Issues

- Choose Low-ESR Capacitors:

- Use capacitors designed for low ESR, such as polymer electrolytic, ceramic, or film capacitors.

- Check Specifications:

- Review datasheets for ESR ratings at the intended operating frequency and temperature.

- Regular Maintenance:

- Replace aging capacitors in critical systems, as ESR increases over time, especially in electrolytic capacitors.

- Parallel Capacitors:

- Place multiple capacitors in parallel to reduce the overall ESR and improve high-frequency performance.

- Use High-Quality Components:

- Opt for capacitors from reliable manufacturers with good thermal stability and durability. Some of the best-quality capacitor brands include Panasonic, Nichicon, Elna, Mundorf, Rubycon, and United Chemi-Con.

Understanding ESR and managing it effectively ensures better performance, reliability, and longevity of electronic circuits.

Capacitor Voltage Rating:

A “50 Volt” rating on a capacitor refers to its maximum working voltage, meaning the maximum voltage it can handle without risk of damage or breakdown. It does not mean the capacitor will always have 50 volts across its terminals.

- Voltage Across the Terminals: The actual voltage across a capacitor depends on the circuit it’s connected to. For example, if a 50 V capacitor is connected in a circuit with 12 V applied, it will charge to 12 V, not 50 V.

- Cathode vs. Anode: For polarized capacitors (like electrolytic capacitors), the cathode is the negative terminal, and the anode is the positive terminal. The voltage across the capacitor is the difference between the potential of the anode and the cathode. The polarity must be correct for polarized capacitors to function safely.

- Non-Polarized Capacitors: If the capacitor is non-polarized, it can handle AC signals or DC voltages applied in either direction, but the voltage must remain below the 50 V rating in both directions.

Key Points:

- A 50 V capacitor can safely handle up to 50 V across its terminals, regardless of which terminal is at the higher potential.

- It does not inherently create or maintain 50 V; the voltage depends on the circuit.

How Capacitors Discharge:

An audio capacitor (or any capacitor) does not discharge all of its stored energy at once. The discharge rate of a capacitor depends on the circuit it is connected to, particularly the resistance or load that it is discharging through.

- Exponential Discharge:

- A capacitor discharges in an exponential manner governed by the time constant Ƭ = RC, where R is the resistance in the circuit and C is the capacitance. (Ƭ is the Greek letter Tau).

- The voltage across the capacitor decreases over time according to the formula: V(t) = V0e–t/Ƭ where V0 = initial voltage, t = time, and Ƭ = RC.

- Discharge Rate:

- If the resistance R is small, the capacitor will discharge quickly.

- If R is large, the discharge will take longer.

- Audio Capacitors:

- Audio capacitors, often used in car audio systems, act as energy reservoirs to stabilize voltage for amplifiers during power surges.

- They discharge energy as needed, rather than all at once, depending on the demands of the audio system.

- For example, during a bass note that requires more power than the battery alone can provide, the capacitor discharges some of its stored energy to supplement the power supply.

Sudden Discharge:

In some cases, if a capacitor is short-circuited (connected directly across a very low resistance), it can discharge very rapidly. However, this is not typical in normal operation and can damage the capacitor or the circuit.

Main Takeaway:

An audio capacitor discharges energy in response to the demands of the circuit, not all at once. The rate and amount of discharge depend on the circuit’s design and the load it is powering.

Capacitor Recharging:

An audio capacitor can begin recharging before it is fully discharged. This behavior is common in many circuits where capacitors are used, including audio applications. The ability of a capacitor to recharge before fully discharging depends on the design and timing of the circuit in which it operates.

How it Happens:

- Continuous Signal Input: In audio circuits, signals are often alternating currents (AC). A capacitor may begin charging in the opposite direction as the signal polarity changes, even if it hasn’t fully discharged from the previous cycle.

- Circuit Design: In some circuits, the capacitor is connected to a power source or charging mechanism (like a resistor or an inductor) that provides a charging current as soon as the voltage across the capacitor drops below a certain level. This allows the capacitor to recharge immediately, even if it hasn’t reached full discharge.

- Time Constant: The capacitor’s charging and discharging depend on the circuit’s time constant Ƭ = RC, where R is resistance and C is capacitance). If the time constant is long compared to the input signal’s period, the capacitor will not fully discharge before the next charging phase begins.

Implications:

- Audio Quality: In audio circuits, this behavior can influence how the capacitor filters signals, which may be desirable or undesirable depending on the application.

- Efficiency: Allowing partial discharge and recharge can maintain smoother operation in circuits like power smoothing or signal coupling, but excessive incomplete discharges may cause inefficiencies or distortions in some designs.

This principle is widely utilized in the design of audio systems, especially in coupling, decoupling, and filtering stages.

Capacitors and Sound Quality:

The quality of capacitors can significantly affect audio sound quality, though the extent of this impact depends on the specific role the capacitor plays in the circuit. In audio equipment, capacitors are used in various applications, including coupling, decoupling, filtering, and tone control. Here’s a breakdown of how capacitor quality can influence sound quality:

- Capacitors in Signal Path (Coupling and Decoupling)

- Coupling capacitors are used to block DC while allowing AC signals (audio) to pass through. These capacitors can have a direct impact on the tonal quality of the sound.

- Decoupling capacitors filter out unwanted noise or ripple from power supplies that can affect the performance of sensitive audio circuits.

- Impact on Sound:

- Non-ideal Capacitors: If a capacitor is of low quality (e.g., cheap, poorly made, or using subpar materials), it can introduce distortion, phase shifts, and even coloration to the audio signal. This can manifest as a loss of clarity, a decrease in bass response, or an overly bright and harsh high end.

- High-Quality Capacitors: Premium capacitors (e.g., film capacitors like polypropylene, or high-grade electrolytic) typically offer better performance by reducing signal degradation, improving transparency, and minimizing distortion or noise. Higher-quality capacitors tend to have more stable characteristics, lower tolerance levels, and better resistance to temperature and voltage fluctuations.

- Capacitors in Power Supply Filtering

- Capacitors in the power supply filter out noise and ripple from the AC mains and stabilize the DC voltage feeding sensitive audio circuitry. If the power supply capacitors are of poor quality, the resulting ripple or noise can affect the audio signal, leading to hum, buzz, or other unwanted interference.

- The size of the ripple at the primary capacitor of the power supply, which is connected to the full-wave rectifier, which in turn is connected to the transformer, is set by the capacitor size.

- The current that the power amp supply rail requires is easily calculated from the power delivered to the load and the load size. A full wave rectifier operates at 120 Hz with a 60 Hz AC line. The capacitor is at full voltage only when the rectifier supply reaches its maximum voltage from the transformer. The diode is off for the rest of the half cycle (8.3 msec). During this time, the capacitor discharges. This is the ripple voltage. Clearly, the larger the primary capacitor, the lower the ripple. The power supply in a power amplifier designed to drive low impedance loads (4 Ω) at high power can approach 100,000 µF. There are some power amplifiers out there with 500,000 µF. The exact sizing is complex and beyond the scope of this tutorial.

- Impact on Sound:

- Poor Filtering: Low-quality capacitors may allow power noise to pass through, causing distortion or hum that is audible in the final audio output.

- Better Filtering: High-quality capacitors (e.g., low ESR electrolytic capacitors) provide cleaner, more stable power to the audio circuits, reducing noise and improving overall sound fidelity.

- Capacitors in Tone Control Circuits

- Capacitors are used in tone control and equalization circuits to filter certain frequencies (high-pass, low-pass, or band-pass filters). The type of capacitor used can affect how these frequencies are shaped and how accurately the circuit performs.

- Impact on Sound:

- Low-Quality Capacitors: These might introduce non-linearities or distort the frequency response, which can alter the tonal balance or the effectiveness of the tone controls.

- High-Quality Capacitors: Good capacitors ensure a more accurate and linear frequency response, preserving the integrity of the audio signal and maintaining natural sound characteristics.

- Capacitor Materials

- Different capacitor materials can affect sound quality in various ways:

- Electrolytic Capacitors: These are commonly used in power supplies but can have higher tolerances, higher ESR (Equivalent Series Resistance), and less stable performance over time, potentially affecting sound quality in sensitive circuits.

- Ceramic Capacitors: Typically low-cost and often used for filtering, ceramic capacitors can have microphonic effects (where they pick up vibrations and transmit them as noise), which can lead to a harsh or grainy sound.

- Film Capacitors: These tend to be favored for signal paths because they have low distortion, good stability, and minimal coloration. Polypropylene, polystyrene, and other high-quality films are often preferred in high-end audio applications.

- Tantalum Capacitors: These are more stable and reliable than electrolytics, though they are generally used in more specific applications. They can offer better performance than electrolytics but still may be less ideal than film capacitors in the signal path.

- Size, Voltage, and Tolerance

- The size and voltage rating of the capacitor are critical for ensuring that it functions properly in the circuit. Using an oversized or undersized capacitor can lead to poor performance.

- Tolerance refers to the accuracy of the capacitor’s value. A capacitor with poor tolerance can result in deviations from the desired frequency response, affecting sound clarity and tonal balance.

- Break-in Period

- Some audiophiles believe that capacitors, especially in high-end audio equipment, “break in” over time, and their characteristics change after being used for a period. While this is debated, the idea is that capacitors might become more stable or exhibit better performance as they age.

Filtering and Smoothing

Coupling and Decoupling

Audio capacitors play a vital role in coupling audio signals between different stages of the circuit. They allow AC signals (audio) to pass through while blocking DC voltages, ensuring efficient signal transfer without distortion.

Additionally, quality capacitors are effective at decoupling unwanted signals, and filtering out high-frequency noise and interference from the audio signal path.

Frequency Response

Bass Response

Quality audio capacitors contribute significantly to enhanced bass response. By providing stable power supplies to amplifiers and smoothing out low-frequency fluctuations, they allow for more accurate reproduction of bass notes. This results in tighter, more controlled low-end performance, giving music a fuller sound without muddiness or distortion.

Treble Performance

High-quality capacitors, particularly film capacitors, are known for providing superior sound quality with lower distortion and enhanced high-frequency response.

This leads to clearer, more detailed treble performance.

Material Considerations

Film vs. Electrolytic

The choice between film and electrolytic capacitors can greatly affect audio performance. Film capacitors, such as polypropylene or polycarbonate, are preferred for their superior sound quality, lower distortion, and better high-frequency response.

Electrolytic capacitors, while offering larger capacitance values in smaller packages, are generally considered to have poor audio characteristics and should be avoided in the signal path when possible.

Capacitor Aging

Over time, capacitors can degrade, potentially impacting sound quality. Electrolytic capacitors, in particular, can lose capacitance value with age, whether in use or not.

This degradation can affect the performance of audio equipment, potentially leading to changes in frequency response or increased noise over time.

Mechanical Considerations

Singing Capacitors

Some capacitors can actually produce unwanted vibrations due to the piezoelectric effect, a phenomenon known as “singing capacitors.” These vibrations can cause the printed circuit board to vibrate, indirectly producing acoustic noise that affects sound quality.

High-quality capacitors and proper circuit design can help mitigate this issue.

Practical Implications

Upgrading Capacitors

Replacing lower-quality capacitors, especially electrolytic ones, with high-quality film capacitors in the audio signal path can lead to noticeable improvements in sound quality.

This upgrade can result in clearer, more detailed sound with better frequency response and lower distortion.

Cost Considerations

While high-quality capacitors, such as polypropylene or polycarbonate types, offer superior audio performance, they are generally more expensive than basic alternatives.

Audio equipment designers must balance performance with cost when selecting capacitors.

In conclusion, the quality of capacitors plays a crucial role in determining the overall sound quality of audio equipment. High-quality capacitors contribute to a cleaner power supply, better signal integrity, improved frequency response, and reduced distortion, all of which translate to a more accurate and enjoyable listening experience.

What is the piezoelectric effect?

The piezoelectric effect in audio capacitors, often referred to as “singing capacitors,” is a phenomenon that occurs in certain types of ceramic capacitors, particularly class II and III ferroelectric capacitors with medium to high dielectric constants.

This effect causes the capacitor to vibrate when an AC voltage is applied, potentially resulting in audible noise if the vibration frequency falls within the 20 Hz to 20 kHz range.

Causes and Characteristics

The piezoelectric effect in capacitors is primarily observed in:

- Ferroelectric capacitors (class II and III)

- Capacitors with medium to high dielectric constants (e.g., X5R, X7R, X8R, Y5V, Y5U, Z5U).

The intensity of the effect is influenced by several factors:

- DC bias

- The ripple amplitude of the applied signal

- PCB design and layout

- Temperature

Impact on Audio Circuits

Mitigating the Piezoelectric Effect:

To reduce the piezoelectric effect in audio circuits, designers can consider the following approaches:

- Use alternative capacitor types:

- Through-hole capacitors

- Capacitors with metal terminations

- Tantalum, aluminum electrolytic, C0G, or NP0 capacitors

- Improve signal quality:

- Reduce ripple amplitude

- Adjust duty cycle (closer to 10% or 90% instead of 50%)

- Use signal frequencies outside the audible range

- Optimize PCB design:

- Use thicker PCBs

- Position capacitors on the edge rather than the center of the board

- Layout capacitors symmetrically on top and bottom layers

- Consider specialized components:

- Kemet’s KPS series of ceramic capacitors, which claim to reduce the piezoelectric effect

By implementing these strategies, audio circuit designers can minimize the impact of the piezoelectric effect and improve overall sound quality in their applications.

Manufacturing an audio capacitor involves several precise steps to ensure the component meets the required specifications for audio applications.

First, the capacitor materials have to be determined according to the capacitor’s intended purpose and quality (cost).

Dielectric: The dielectric material separates the conductive material layers from one another. Otherwise, the product would not be a capacitor. Dielectric materials include polypropylene, polyester, or paper. The choice depends on the desired properties, such as low loss and stability.

Electrodes: Metal foils (copper) or thin metal films (e.g., aluminum, tantalum, zinc), are used as electrodes. Metal plates at either end of the two conductive layers are designated as anode and cathode. The anode is connected to the + pole of the electrical source, and the cathode is connected to the – pole of the electrical source.

Foil capacitors and film capacitors are both types of capacitors, but they differ in their construction, materials, and applications. Here’s a breakdown of their differences:

- Construction

- Foil Capacitor:

- Made using alternating layers of metal foil (usually aluminum) and a dielectric material (such as paper or plastic).

- The foil serves as the electrodes, while the dielectric layer insulates the electrodes.

- Typically, the layers are rolled or stacked and then encased.

- Film Capacitor:

- Made with a thin plastic film as the dielectric, with metal layers (often aluminum or zinc) deposited on or attached to the film to serve as the electrodes.

- The film and electrode are either wound into a roll or stacked.

- Can use metalized film (a very thin metal layer) or discrete metal foil as electrodes.

- Dielectric Material

- Foil Capacitor:

- Typically uses thicker dielectric materials like paper, polypropylene, or polyester.

- This makes them larger and often less precise in capacitance value.

- Film Capacitor:

- Uses extremely thin plastic films (polypropylene, polyester, polystyrene, etc.) as the dielectric.

- Allows for higher precision and miniaturization.

- Performance Characteristics

- Foil Capacitor:

- Higher current handling capability due to the thicker metal electrodes.

- Tends to be more robust and durable, making them suitable for high-power and high-voltage applications.

- Can handle larger capacitance values and higher ripple currents.

- Film Capacitor:

- Better stability and precision in capacitance value over time and temperature.

- Lower equivalent series resistance (ESR) and lower losses at high frequencies. See page 20 for an explanation of ESR.

- Typically used for lower current and lower capacitance applications but can still handle high voltage.

- Applications

- Foil Capacitor:

- Commonly used in power electronics, motor run applications, and situations where large capacitance and high current handling are required.

- Suitable for AC circuits and high-stress environments.

- Film Capacitor:

- Widely used in signal processing, audio circuits, and applications requiring high precision and low noise.

- Common in DC circuits, timing, and coupling/decoupling applications.

- Size and Cost

- Foil Capacitor:

- Larger and bulkier due to the thicker construction.

- Generally more expensive because of the amount of material used.

- Film Capacitor:

- Smaller and more compact due to the thin film.

- Often more cost-effective for precision applications.

Summary

Foil capacitors are robust and better for high-current, high-power applications, while film capacitors are precise, stable, and suited for lower-power, high-frequency, and signal applications.

Silver is sometimes used in foil and film capacitors, but its application depends on the specific type and purpose of the capacitor. Here’s how silver might be used in these capacitors:

Silver Foil Capacitors

- Silver Foil:

- Silver foil can be used as the electrode in some high-end or specialized capacitors.

- This is typically found in applications where superior electrical conductivity and low resistance are crucial, such as in audiophile-grade capacitors for high-fidelity audio systems.

- Cost Consideration:

- Silver foil capacitors are rare because silver is significantly more expensive than alternatives like aluminum. Their use is justified only in high-performance, niche markets.

Silver Film Capacitors

- Silver Metalization:

- In metalized film capacitors, silver can be used as the thin metallic layer deposited onto the dielectric film (e.g., polypropylene or polyester).

- This layer forms the capacitor’s electrodes and offers excellent conductivity and adhesion to the film.

- High-Performance Applications:

- Silver-metalized film capacitors are found in precision applications, such as RF circuits, high-frequency applications, or other scenarios requiring very stable and low-loss capacitors.

- Hybrid Designs:

- Some capacitors use a combination of silver and other metals (like aluminum or zinc) to balance performance and cost.

Why Silver?

- Advantages:

- High electrical conductivity.

- Excellent thermal and chemical stability.

- High precision and low losses, especially in high-frequency applications.

- Limitations:

- High cost compared to other metals like aluminum or zinc.

- Less commonly used in standard capacitors because of price and the availability of other suitable materials.

Silver is not commonly used in everyday foil or film capacitors because of its high cost, but it can be found in specialized, high-performance applications where its unique properties—such as superior conductivity and stability—offer distinct advantages.

Dielectric Film Preparation: Thin sheets of dielectric material are manufactured through extrusion, casting, or spraying to achieve uniform thickness and high dielectric purity. In audio capacitors, precision will minimize distortion and ensure consistent performance.

Electrode Coating: Two separate metal electrodes are applied to the dielectric material, one for the anode and one for the cathode. For film capacitors, a metal layer is often vacuum-deposited onto the dielectric. If the electrodes are metal foils, they are situated alongside the dielectric material during winding or assembly. Dielectric materials can sometimes be sprayed onto the surface of the electrode material. Note that the dielectric material is only on one side of the electrode. Otherwise, there would be two layers of dielectric between each layer of electrode when the electrode is wound.

Secrets Sponsor

Winding or Stacking:

Wound Capacitors: The dielectric and electrode layers are tightly wound into a cylindrical or oval shape. This is common for film capacitors.

HERE IS A YOUTUBE VIDEO SHOWING HOW A COPPER FOIL CAPACITOR IS WOUND (© DUELUND):

YouTube Video © Duelund

Stacked Capacitors: Layers of dielectric and electrodes are stacked (folded), ensuring a compact and stable design.

Adding the Dielectric: To improve electrical properties and reliability, the wound or stacked core is often impregnated with a dielectric fluid (e.g., oil) or resin. This process fills voids and enhances insulation.

Forming: The capacitor undergoes a “re-forming” step to repair any imperfections in the oxide layer.

Encasing: The capacitor core is encapsulated in a protective casing. Common materials include plastic, epoxy, or metal canisters, depending on the application. Aluminum Capacitors: Placed in an aluminum can and sealed with a rubber bung or plastic cap. Tantalum Capacitors: Encased in an epoxy resin or molded package.

Encasing protects the capacitor from environmental factors like humidity and mechanical stress.

Attaching the Leads: Metal (copper or silver) leads or terminals are attached to the electrodes to allow for integration into circuits. This is done using soldering or welding techniques.

Testing and Quality Control: Each capacitor undergoes rigorous testing to ensure it meets specifications. This includes capacitance measurement, ESR (Equivalent Series Resistance) testing, voltage withstand and leakage tests, and frequency response testing (especially important for audio capacitors to ensure linearity and low distortion). High-end audio capacitors may also be hand-selected and matched for precise tolerances.

Labeling and Packaging: Once approved, capacitors are marked with specifications like capacitance, voltage rating, and manufacturer information. They are then packaged for distribution, with some high-end audio capacitors being packed individually to avoid damage.

Key Differences Between Aluminum and Tantalum Capacitors

| Type | Aluminum Electrolytic Capacitor | Tantalum Electrolytic Capacitor |

| Anode Material | Etched aluminum foil | Sintered tantalum powder |

| Dielectric | Aluminum oxide | Tantalum pentoxide |

| Cathode | Liquid/gel electrolyte | Solid manganese dioxide or polymer |

| Encapsulation | Aluminum can with electrolyte seal | Epoxy resin or molded package |

Dielectric: This is an insulating material placed between the two conductive plates (or electrodes) of a capacitor. The dielectric increases the capacitor’s ability to store charge by reducing the electric field between the plates, allowing for greater capacitance without electrical breakdown.

Anode and Cathode: These are the two distinct and separate conductive plates or electrodes in the capacitor:

The anode is typically the plate connected to the positive terminal of the voltage source.

The cathode is connected to the negative terminal.

The dielectric is crucial for the capacitor’s function, but it is not itself a conductive part and does not act as an electrode. Instead, it serves to separate the anode and cathode while affecting the capacitor’s storage capacity and voltage rating.

In a capacitor, the anode is typically connected to the innermost layer of the electrode. Here’s why:

Capacitors are generally composed of two distinct conductive layers (electrodes) separated by a dielectric material. In some types of capacitors, particularly electrolytic capacitors, the anode is a specially treated metal foil (often aluminum or tantalum) that forms a thin oxide layer serving as the dielectric. This oxide layer is formed on the surface of the anode, making it the innermost layer relative to the capacitor’s structure.

Key Points:

- Anode Position: The anode is connected to the innermost layer because it is where the dielectric oxide is formed.

- Cathode: The outermost layer (cathode) in the capacitor serves as the second electrode, usually in contact with an electrolyte or conductive material.

- Design Rationale: This arrangement maximizes the surface area and ensures a stable structure for capacitance.

This structure is especially relevant for electrolytic capacitors. For other types of capacitors, such as ceramic or film capacitors, the concept of “anode” and “cathode” aren’t directly applicable in the same way. Instead, they have symmetric electrodes.

Types of Capacitors:

- Electrolytic Capacitors:

- The anode and cathode are clearly defined and involve a metal foil and electrolyte, respectively.

- The anode’s oxide layer acts as the dielectric.

- Ceramic Capacitors:

- The electrodes are separated by ceramic as the dielectric.

- The electrodes are often alternating layers of metal embedded within the ceramic body.

- Film Capacitors:

- The electrodes are thin metal layers or foils separated by a plastic film dielectric.

- Foil Capacitors:

In all these types, the anode and cathode are two distinct layers and are separated by the dielectric, ensuring no direct electrical contact while allowing the capacitor to store energy.

Capacitors can be polarized (with a + and – terminal) or non-polarized.

The main difference between a polarized capacitor and a non-polarized capacitor lies in their construction and how they must be connected in a circuit:

Polarized Capacitors:

- Orientation: These capacitors have a specific polarity and must be connected correctly in a circuit, with the positive terminal (anode) connected to a higher voltage than the negative terminal (cathode).

- Types: Common types include electrolytic capacitors (e.g., aluminum or tantalum).

- Capacitance: Typically offer higher capacitance values (e.g., microfarads to millifarads).

- Applications:

- Used in DC circuits.

- Suitable for applications where the voltage has a fixed polarity, such as power supplies, coupling, and filtering.

- Risk: Connecting a polarized capacitor backward can damage the capacitor, leading to leakage, overheating, or even explosion.

Structure of a Non-Polarized Capacitor:

- Electrodes:

- Two separate conductive layers act as the electrodes.

- These layers can be made of metal foils, thin films, or deposited metal depending on the capacitor type.

- Dielectric:

- A non-conductive material between the electrodes prevents direct electrical contact.

- Common materials include ceramic, plastic film, mica, or paper.

- The dielectric defines the capacitor’s voltage rating and stability.

- Symmetry:

- The construction is symmetric, so there is no designated positive or negative terminal.

- This symmetry allows the capacitor to handle AC signals or voltage of any polarity without damage.

Examples of Non-Polarized Capacitors:

- Ceramic Capacitors: Thin metal layers separated by ceramic material.

- Film Capacitors: Metalized plastic films as electrodes with plastic as the dielectric.

- Mica Capacitors: Metal layers separated by mica sheets.

- Electrolytic Non-Polarized Capacitors: Specially designed with dual anodes to function without polarity.

Functionality:

The presence of two distinct electrode layers ensures the capacitor can store and release electrical energy while maintaining electrical isolation via the dielectric. This structure is fundamental to all capacitors, whether polarized or non-polarized.

Non-polarized capacitors are versatile components widely used in various types of audio circuits. Their primary function is to handle AC signals without introducing polarity constraints. Below are common audio circuit applications where non-polarized capacitors are used:

- Signal Coupling

- Applications: Amplifiers, mixers, and preamps.

- Purpose: Non-polarized capacitors are used to couple audio signals between stages of a circuit, blocking DC while allowing AC (audio signals) to pass through. This prevents unwanted DC offsets from interfering with the next stage.

- Decoupling/Bypassing

- Applications: Power supply circuits in audio equipment.

- Purpose: They filter out AC noise or fluctuations on the DC supply lines, ensuring clean power delivery to audio components.

- Tone Control and Equalization

- Applications: Tone control circuits in amplifiers, equalizers, and audio processors.

- Purpose: Non-polarized capacitors are used in filters (high-pass, low-pass, band-pass) to shape the frequency response of the audio signal, allowing control over bass, treble, and other frequencies.

- Crossover Networks

- Applications: Loudspeaker systems.

- Purpose: In passive crossover networks, non-polarized capacitors divide audio signals into frequency bands (e.g., high frequencies for tweeters, and low frequencies for woofers).

- Oscillators

- Applications: Audio signal generators and modulation circuits.

- Purpose: Non-polarized capacitors are integral to timing and frequency-determining components in oscillators, which produce specific tones or signals.

- Feedback and Stabilization

- Applications: Operational amplifier (op-amp) circuits in most audio equipment. The capacitor selection is basically the same in a discrete power amp, although the unknown load impedance presents additional design considerations.

- Purpose: They control gain and stability in amplifier circuits, helping to define frequency response and prevent oscillations.

- Delay and Reverb Circuits

- Applications: Effects processors for musical instruments and audio production.

- Purpose: Non-polarized capacitors are part of the time-delay networks, manipulating audio signals for effects.

- Filter Circuits

- Applications: Noise reduction, audio shaping, and processing systems.

- Purpose: Capacitors are essential in active and passive filter designs for audio signal processing.

Key Reasons for Using Non-Polarized Capacitors:

- Bidirectional Signal Handling: Ideal for AC signals, as they can handle current flow in both directions without risk of polarity reversal damage.

- Low Distortion: They introduce minimal distortion, critical for maintaining audio fidelity.

- Wide Capacitance Range: Available in small capacitance values suitable for audio-frequency applications.

Popular types of non-polarized capacitors used in audio circuits include film capacitors (e.g., polyester, polypropylene), ceramic capacitors, and sometimes tantalum or aluminum electrolytic capacitors in non-polarized configurations.

While high-end products may have mostly non-polarized capacitors, a signal path between a lower-priced phono preamp and a power amp typically runs through many standard polarized electrolytic caps. Open up a mass market AVR and you will see dozens of them. Also, in the feedback loop, polarized caps will be found at the ground end of a feedback loop to bring the feedback to unity at DC, reducing DC offset.

To get a good low-frequency response before the feedback is reduced to prevent a DC offset, these caps can be 1,000 µF if thermal noise in the resistor is a concern. The fix is to remove the cap and add a stage called a DC servo. As the name implies, this added circuit forces the output to be close to 0 Volts at DC. It uses an op-amp.

Graphene Supercapacitors – The Newest Capacitor Technology

Graphene supercapacitors store energy through electric double-layer capacitance (EDLC) and sometimes pseudocapacitance.

EDLC (Electrostatic Storage) – Graphene’s high surface area allows more charge to accumulate at the electrode-electrolyte interface, improving capacitance.

Pseudocapacitance (Electrochemical Storage) – Some designs use graphene oxide or functionalized graphene to introduce faradaic reactions, increasing energy density.

Some supercapacitors use graphene at a thickness of just one atom. Graphene is a single layer of carbon atoms arranged in a hexagonal lattice, and it’s an excellent material for supercapacitors due to its exceptional electrical conductivity, high surface area, and mechanical strength.

The structure of a supercapacitor consists of two carbon (graphene) electrodes separated by an electrolyte solution and porous paper, polymer membrane, or nonwoven fabric. The electrolyte consists of an acid, such as sulfuric acid (H2SO4) or sodium bisulfate (NaHSO₄), or a base (alkali), such as potassium hydroxide (KO4). In conventional electrolytic capacitors, the electrolyte is typically a solution containing chemicals like borax, phosphate, or carbonate, often dissolved in a solvent like ethylene glycol. This is a a lot less toxic than the strong acids or alkalis in supercapacitors. Just imaging the damage a supercapacitor in an audio amplifier could cause if it exploded, as conventional audio capacitors sometimes do, splattering sulfuric acid all over the PCBs. This is why the development of supercapacitors for audio amplifier applications will have to take this possibility into consideration, and, hopefully, use less dangerous electrolytes.

In graphene-based supercapacitors, the ultrathin nature of graphene allows for a high charge-storage capacity. Because graphene has a theoretical surface area of up to 2,630 m² per gram, it enables a greater interaction with electrolytes, leading to higher energy and power densities compared to conventional carbon-based supercapacitors. Currently (February, 2025) a supercapacitor, 45 Volt, 165 Farad capacitance is available for $1,142. To put this capacitance in perspective, a high-quality stereo audio power amplifier, 250 Watts per channel, might have 80,000 µF of power supply capacitance (0.08 Farads).

In practical applications, graphene sheets often tend to stack together, reducing the effective surface area. To mitigate this, researchers developed porous graphene structures, aerogels, or composites to maintain high capacitance and improve ion transport.

Graphene supercapacitors could potentially be used in audio amplifiers, though they are not yet mainstream in this application. Here’s why they could be beneficial:

- Fast Power Delivery – Supercapacitors can provide quick bursts of power, which is useful for handling dynamic audio peaks without distortion.

- Low Equivalent Series Resistance (ESR) – Graphene supercapacitors have very low ESR, reducing power losses and improving efficiency.

- Long Lifespan – Unlike traditional capacitors, they last for millions of charge cycles, making amplifiers more durable.

- Energy Efficiency – They can stabilize power supply fluctuations, reducing noise and improving audio quality.

Potential Uses in Audio Systems

- Power Supply – They can serve in the traditional manner to smooth out power fluctuations in high-end amplifiers.

- Battery-Assisted Audio Gear – Could improve efficiency in portable speakers, DACs, and headphone amps by supplementing batteries.

- Dynamic Bass Enhancement – Their ability to deliver fast, high-current bursts could enhance transient response for deeper bass reproduction.

Challenges

- Cost – Graphene supercapacitors are still expensive to manufacture at scale.

- Energy Density – While they provide quick bursts of power, they cannot replace traditional batteries in long-duration applications.

- Circuit Design Compatibility – Audio circuits may need to be redesigned to fully take advantage of their capabilities.

Key advancements and approaches in this field:

- Porous and 3D Graphene Structures

To overcome the issue of graphene sheets stacking together, researchers have developed:

- Graphene aerogels and foams: These structures maintain high surface area and allow better ion diffusion.

- Laser-induced graphene (LIG): A method where a laser is used to convert carbon-based materials into porous graphene directly on a substrate, useful for flexible supercapacitors.

- Graphene-Composite Electrodes

Scientists are combining graphene with other materials to enhance performance:

- Graphene with metal oxides (e.g., MnO₂, RuO₂): Improves charge storage by leveraging the pseudocapacitance effect.

- Graphene with conductive polymers (e.g., polyaniline, polypyrrole): Boosts capacitance while maintaining mechanical flexibility.

- Solid-State and Flexible Supercapacitors

Graphene is being used in flexible and wearable electronics:

- Flexible solid-state supercapacitors: Use gel electrolytes (like PVA-H₂SO₄) instead of liquid electrolytes, making them safer and more versatile.

- Printed graphene supercapacitors: Graphene ink can be used to print energy storage devices onto flexible substrates.

- Hybrid Supercapacitors (Battery-Supercapacitor Fusion)

Graphene is being integrated into hybrid energy storage systems that combine battery-like materials with supercapacitors to provide both high energy and high power. Examples include:

- Graphene-lithium hybrid capacitors: Offer much higher energy densities than traditional supercapacitors.

- Graphene-silicon hybrids: Aimed at bridging the gap between supercapacitors and batteries for high-performance applications.

- Industry Applications and Commercialization

Graphene-based supercapacitors are moving toward commercialization in:

- Electric vehicles (EVs): For rapid energy bursts and regenerative braking.

- Wearable electronics: Powering smart textiles and medical sensors.

- Grid energy storage: Offering a fast-response supplement to renewable energy sources.

Graphene supercapacitors could improve power management, efficiency, and sound quality in high-end amplifiers. While they are not yet common in consumer audio gear, ongoing research and cost reductions could lead to their adoption in premium audio equipment in the future.

Capacitors can influence the sound quality of audio systems by affecting the clarity, tonality, noise levels, and overall fidelity of the audio signal. In signal path circuits, high-quality capacitors are typically preferred for their ability to maintain signal integrity with minimal distortion or coloration. In power supply circuits, good filtering capacitors help ensure a clean and stable signal. While the type and quality of capacitors can play a role, the overall design of the audio equipment, including the circuitry and components, will also significantly influence the final sound quality.

While the designer, with an infinite budget, would pick the best capacitor for each spot in the circuit, this is impossible for affordable equipment. The art of analog electronics design involves making compromises with minimal change to the measured results, which keeps the subjective performance as close as possible to the cost-no-object design.

However, it’s important to note that capacitor quality tends to be just one factor in a larger system. Other components like resistors, op-amps, and the power amplifier design also play crucial roles in determining the overall sound performance.

OTHER TECHNICAL ARTICLES OF INTEREST

Vacuum Tubes (Valves) in Audio, Video, and Other Industries – History, The Different Types, and How They Work – John E. Johnson, Jr.

An Audiophile’s Guide to Quantization Error, Dithering, and Noise Shaping in Digital Audio – John E. Johnson, Jr.

The Design and Function of Transistors in Audio: Past, Present, and Future – Robert Cordell

Life on the Edge – A Personal Perspective on the Past, Present, and Future of Class D Audio Amplifiers – Bruno Putzeys

Raising the Bar on Speaker Performance. A Loudspeaker Designer’s Perspective – Bill Dudleston

The Sound of Tubes – Why is it So Good? – Lukasz Feliks

https://hometheaterhifi.com/30th-anniversary/the-now/the-sound-of-tubes-why-is-it-so-good/

REFERENCES

Picking Capacitors, Walt Jung (1980), https://web.archive.org/web/20160321164026/http://www.waltjung.org/PDFs/Picking_Capacitors_1.pdf

https://web.archive.org/web/20160321164026/http://www.waltjung.org/PDFs/Picking_Capacitors_2.pdf

Cordell, Bob. Designing audio power amplifiers. 2nd edition McGraw Hill Professional, 2019. Pages 222-232

Self, Douglas. Small signal audio design. Focal Press, 2020. Chapter 9

Selecting Capacitors to Minimize Distortion in Audio Applications, Zak Kaye, 2023, https://www.ti.com/lit/an/slyt796a/slyt796a.pdf?ts=1736562680972

Capacitor Characteristics, Rod Elliott, 2024, https://sound-au.com/articles/capacitors.htm

What is an Audio Capacitor and Why Does it Matter?, Blikae Electronic, 2024, https://www.blikai.com/blog/capacitors/what-is-an-audio-capacitor-and-why-does-it-matter

Audio Grade Capacitors: What They Are and Why They Matter?, IC Component limited, 2009, https://www.ic-components.com/blog/audio-grade-capacitors-what-they-are-and-why-they-matter.jsp

AUDIOPHILE CAPS: Beyond the simple “re-cap”, Analog Engineering Associates, 2015, https://aeaaudio.com/audiophile-quality-capacitors-going-beyond-the-simple-re-cap/

Capacitors in Audio Crossover Networks – Audio-optimized Film Capacitors, Tom Colella, Electrocube, 2025, How https://www.electrocube.com/pages/capacitors-in-audio-crossover-networks-data-sheet

How Capacitors Work, M. Brain, C. Pollette, How Stuff Works, https://electronics.howstuffworks.com/capacitor.htm

The Effects of Audio Capacitors on Sound Quality, Authors: Acoustics Research Center

Measured Differences Between Capacitors for Audio Applications, Conrad Hoffman

Capacitor Technologies, Applications, and Reliability, Authors: NASA

Capacitors: Technology and Trends, R. P. Deshpande

Audio-Grade Capacitors: Capacitors & Sound Quality, Arrow.com

Conway, B. E. (1999). Electrochemical Supercapacitors: Scientific Fundamentals and Technological Applications. Springer.

Akinwolemiwa, B., Peng, C., & Chen, G. Z. (2018). Supercapacitors: Electrochemical Energy Storage for the Future. CRC Press.

Burke, A. (2007). Ultracapacitors: The Future of Energy Storage. Nova Science Publishers.

Simon, P., & Gogotsi, Y. (2008). “Materials for electrochemical capacitors.” Nature Materials, 7(11), 845-854. [DOI: 10.1038/nmat2297]

Zhang, L. L., & Zhao, X. S. (2009). “Carbon-based materials as supercapacitor electrodes.” Chemical Society Reviews, 38(9), 2520-2531. [DOI: 10.1039/B813846J]

Borenstein, A., Hanna, O., Attias, R., Luski, S., Brousse, T., & Aurbach, D. (2017). “Carbon-based composite materials for supercapacitor electrodes: A review.” Journal of Materials Chemistry A, 5(25), 12653-12672. [DOI: 10.1039/C7TA00852F]

Wang, G., Zhang, L., & Zhang, J. (2012). “A review of electrode materials for electrochemical supercapacitors.” Chemical Society Reviews, 41(2), 797-828. [DOI: 10.1039/C1CS15060J]

Miller, J. R., & Simon, P. (2008). “Electrochemical capacitors for energy management.” Science, 321(5889), 651-652. [DOI: 10.1126/science.1158736]

Zhu, Y., Murali, S., Stoller, M. D., Ganesh, K. J., Cai, W., Ferreira, P. J., … & Ruoff, R. S. (2011). “Carbon-based supercapacitors produced by activation of graphene.” Science, 332(6037), 1537-1541. [DOI: 10.1126/science.1200770]

Liu, C., Li, F., Ma, L. P., & Cheng, H. M. (2010). “Advanced materials for energy storage.” Advanced Materials, 22(8), E28-E62. [DOI: 10.1002/adma.200903328]