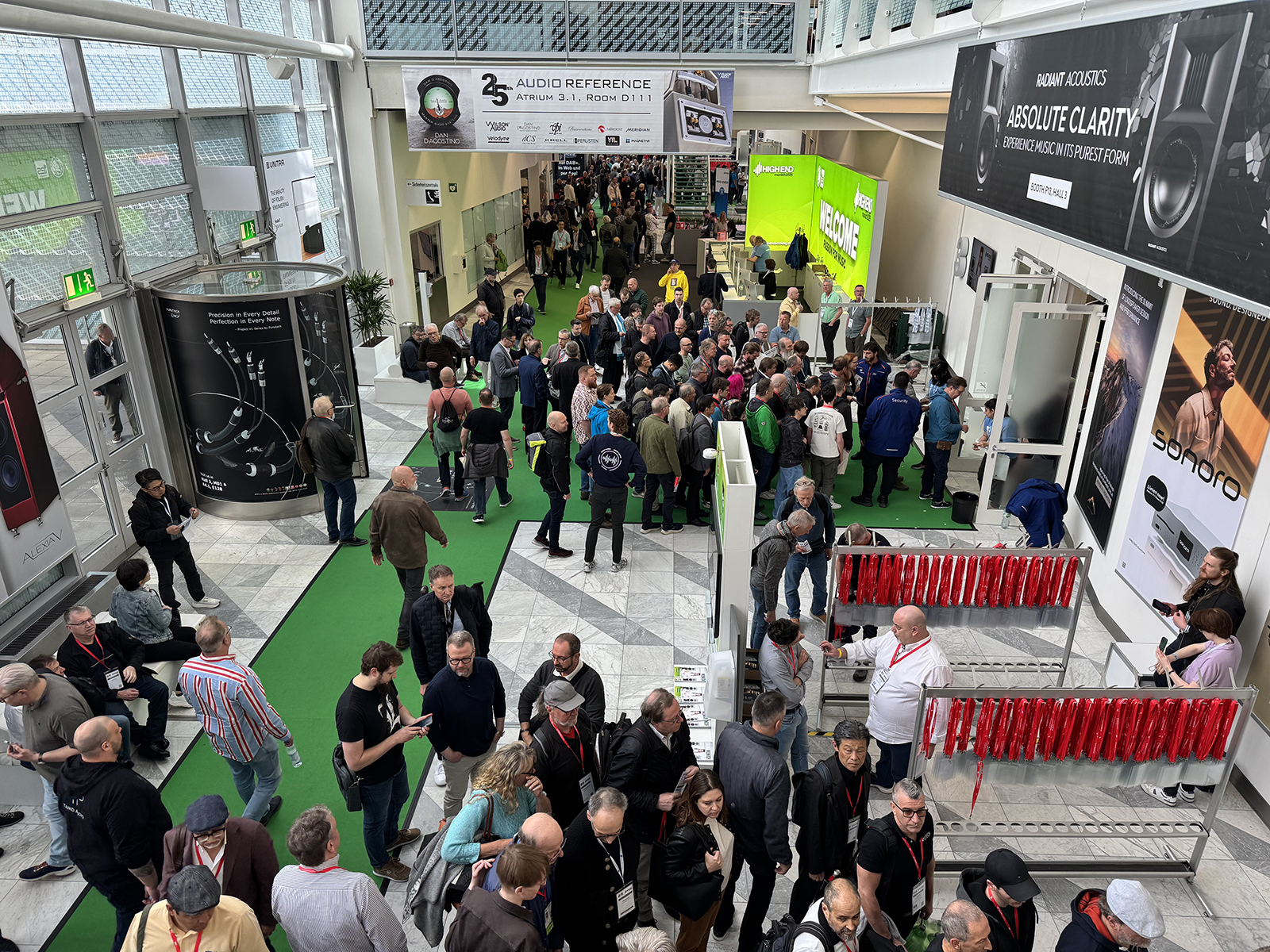

That essentially sums up the week I spent in Munich this year to cover the final Munich High-End show and to visit a couple of jewels in the German audio scene.

VIABLUE Cables and AVM are a couple of audio brands that I have become well acquainted with over the last few years. Here at SECRETS, we have reviewed some of their offerings and each time have come away suitably impressed. VIABLUE and AVM particularly appeal to me because both companies are small and scrappy, yet they produce a level of product that is exceptional, with a quality of workmanship that is in the best German tradition. I’ve also gotten to know the principal folks from both brands over the years, and let’s just say that the quality and passion that are apparent in each company’s product lines are a direct extension of the quality of people who are running the show.

So, the day after Munich High-End wrapped up, the fine crew from Fidelity Imports (official US distributor for both brands), piled me and a few other select audio “journos” in some cars and we briskly hustled west, Autobahn style, to our first destination.

VIABLUE Cables

The first stop on the “Audiophile Schnitzel Express” was VIABLUE, which was located in Malsch, about a three-hour drive from Munich.

Anke Patt and Lars Rewesa of VIABLUE.

Anke Patt and Lars Rewesa of VIABLUE.

I’ve known Anke Patt, CEO at VIABLUE, for a few years now, and in an industry full of, shall we say, “colorful characters” (especially on the audio cable side of things), she is a pragmatic and refreshingly normal individual with a wicked sense of humor. I was intrigued with VIABLUE’s cable products since I was first introduced to them at least two years ago, and became a full-fledged fan since I had a chance to review them for myself around this time last year. Anke and her team do not make fanciful claims that their cables perform sonic miracles; they DO claim that their cables are neutral and transparent, allowing your system to perform at its best. They are also exceedingly well-designed, built to a very high standard, and look utterly “bitchin” to boot. As such, I was interested to get a closer look at the goings-on behind the scenes.

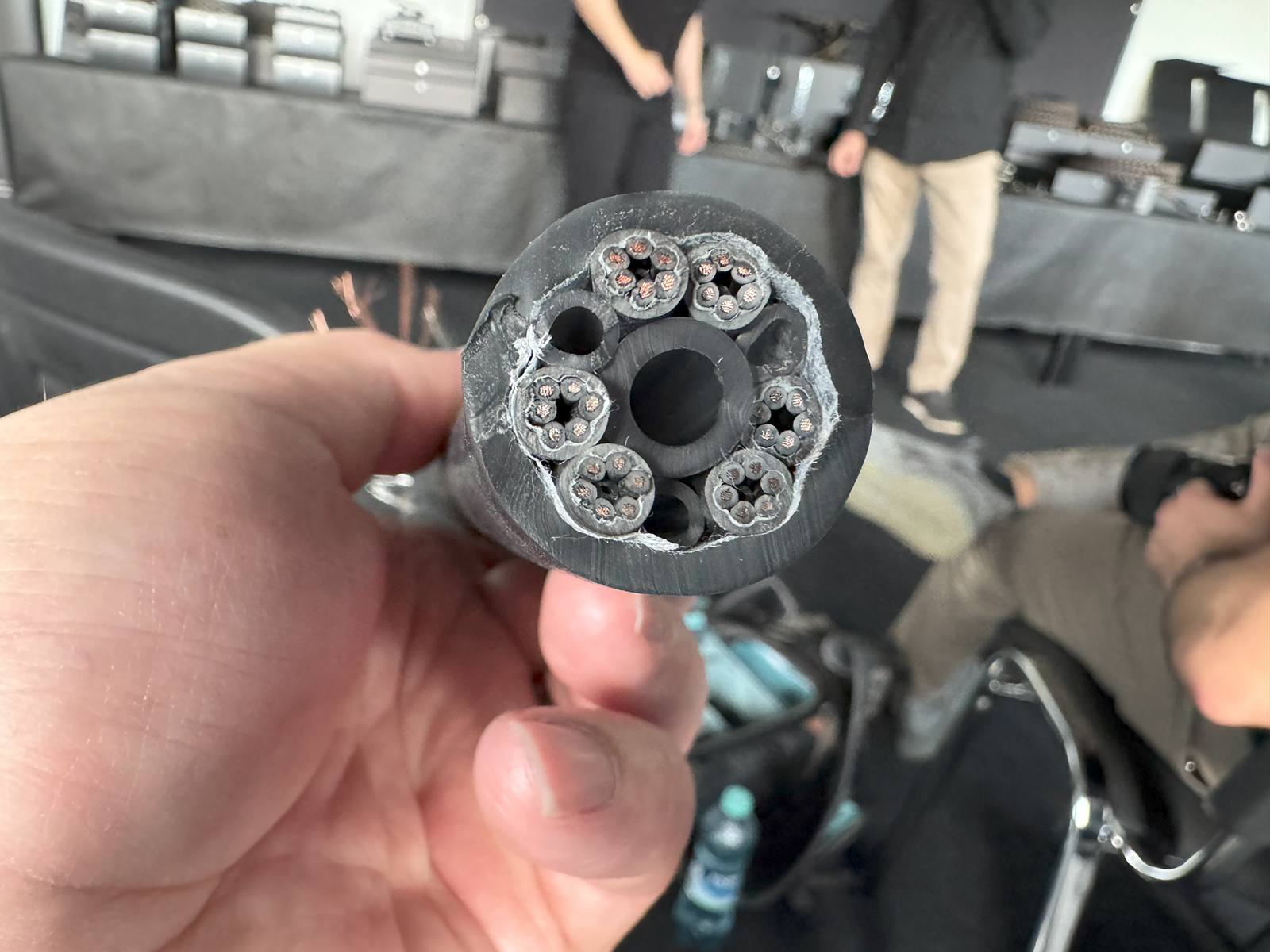

VIABLUE Speaker Cable Cross Section.

VIABLUE Speaker Cable Cross Section.

VIABLUE Power Cable Exploded View.

VIABLUE Power Cable Exploded View.

VIABLUE Speaker Cable Binding Posts.

VIABLUE Speaker Cable Binding Posts.

VIABLUE’s leadership team consists of Founder Jörg Loidl, COO and Technical Director Lars Rewesa, and CEO Anke Patt. The company itself is small, but the manufacturing team is quite skilled and prolific, having amassed a fairly comprehensive product line with plenty of stock of cables in standard sizes ready to ship at a moment’s notice. VIABLUE is also open to doing custom work for specific needs, should that be requested. Everything VIABLUE makes is produced in Germany and hand assembled in their Malsch facility. Originally started by Jörg in 2001 out of frustration due to the quality of cables he found on the market at the time, which were geared for the recording industry. Business steadily grew to the point where Lars and Anke joined in 2007 and 2013, respectively.

From L to R:

Lars Rewesa, technical director * Anke Patt, owner/CEO * Andrea Bantle, head of our assembly * Stefan Weber, customer service Europe * Pascal Grafmüller, customer service US, Asia

This is very much a “family” operation, with the care and attention to detail afforded to their products being readily visible. At the time of our visit, a new and more expansive facility was under construction for the company to move into, hopefully later on this year.

Both Anke and Lars were available for a little “Show and Tell” about their company and its products, which you can see above. Jörg was not available during our visit. The company’s inside joke is that Jörg is never seen, like the never-revealed “Charlie” from the 70s TV show Charlie’s Angels. The hooded mannequin that looms in their presentation room is supposed to represent Jörge, mysteriously watching over everything!

Secrets Sponsor

AVM

The following day, and in the same general vicinity as VIABLUE, we paid a visit to AVM (Audio Video Manufaktur GmbH). AVM is known for making intelligently designed audio components with excellent connectivity, high performance, a certain level of expandability, and a tasteful dash of “bling” (see the chrome-like Cellini Finish).

Udo Besser, founder/CEO of AVM.

Udo Besser, founder/CEO of AVM.

Ekinc Ufuk (GM/COO), Udo Besser (CEO), Nico Schneider (R&D).

Ekinc Ufuk (GM/COO), Udo Besser (CEO), Nico Schneider (R&D).

We were graciously hosted by the company’s founder, Udo Besser. It’s easy to see that Udo is very proud of what AVM has become over its almost 40 years of existence. This was readily apparent as he walked us through what was essentially a holding area of gear that seemed more like a company time capsule.

There was an array of gear that included some of AVM’s earliest pieces, company milestone products, along with some pieces of customer gear, of various vintages, that were in for servicing.

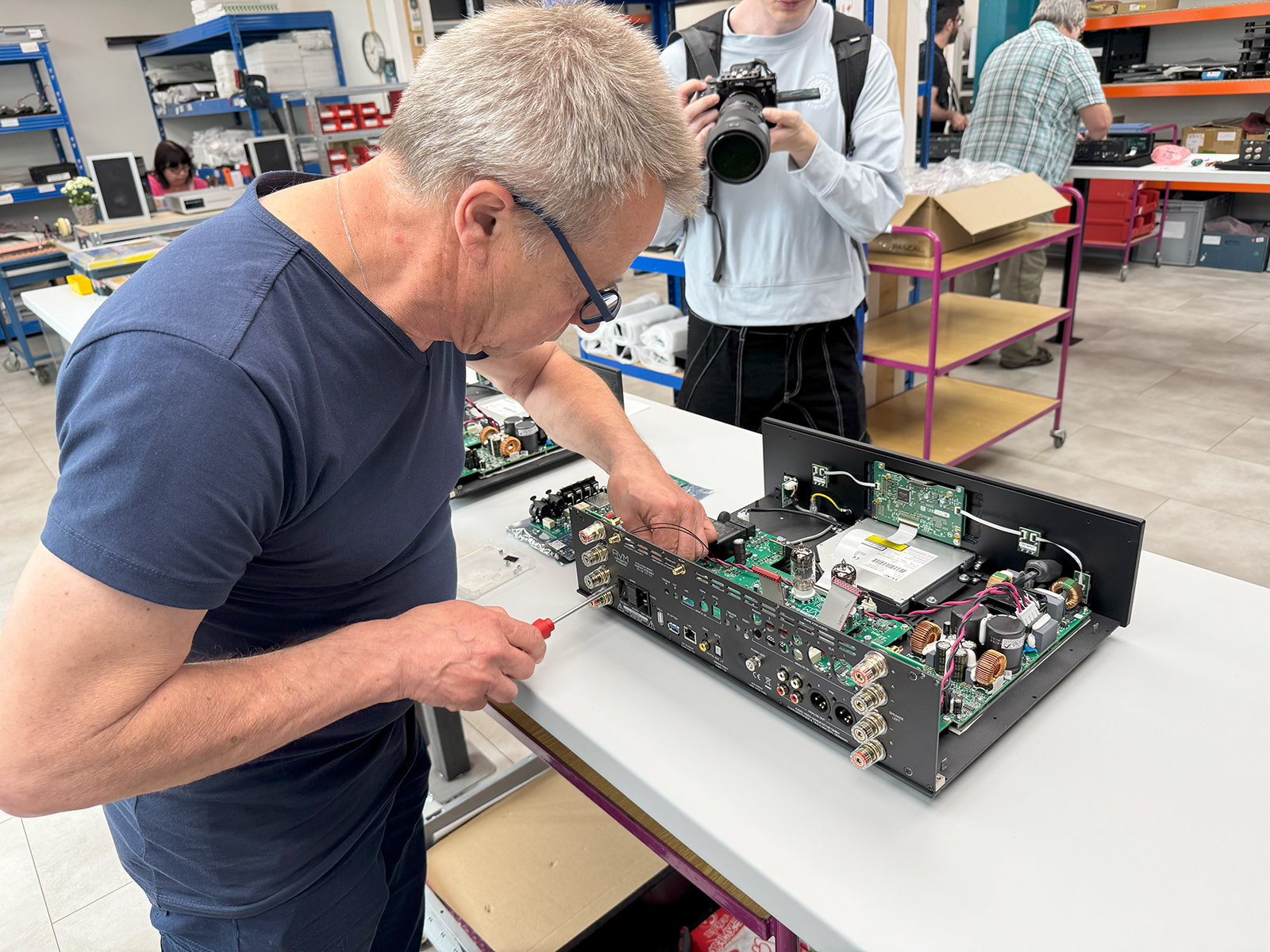

We were then led into another building, which housed AVM’s assembly and quality control area. Now, with the breadth of AVM’s product offerings, I was initially imagining we would be walking through some big “cleanroom” style facility with lots of serious German people wearing lab coats and all that sort of thing. What I encountered was a surprisingly small, tightly knit, talented group of folks who, by all accounts, were very passionate about what they were doing there. Hand-assembling everything with the greatest of care. Not a single pocket protector in sight!

All the electronics are manufactured here; the bookshelf speakers and turntables are produced with the assistance of specialists elsewhere.

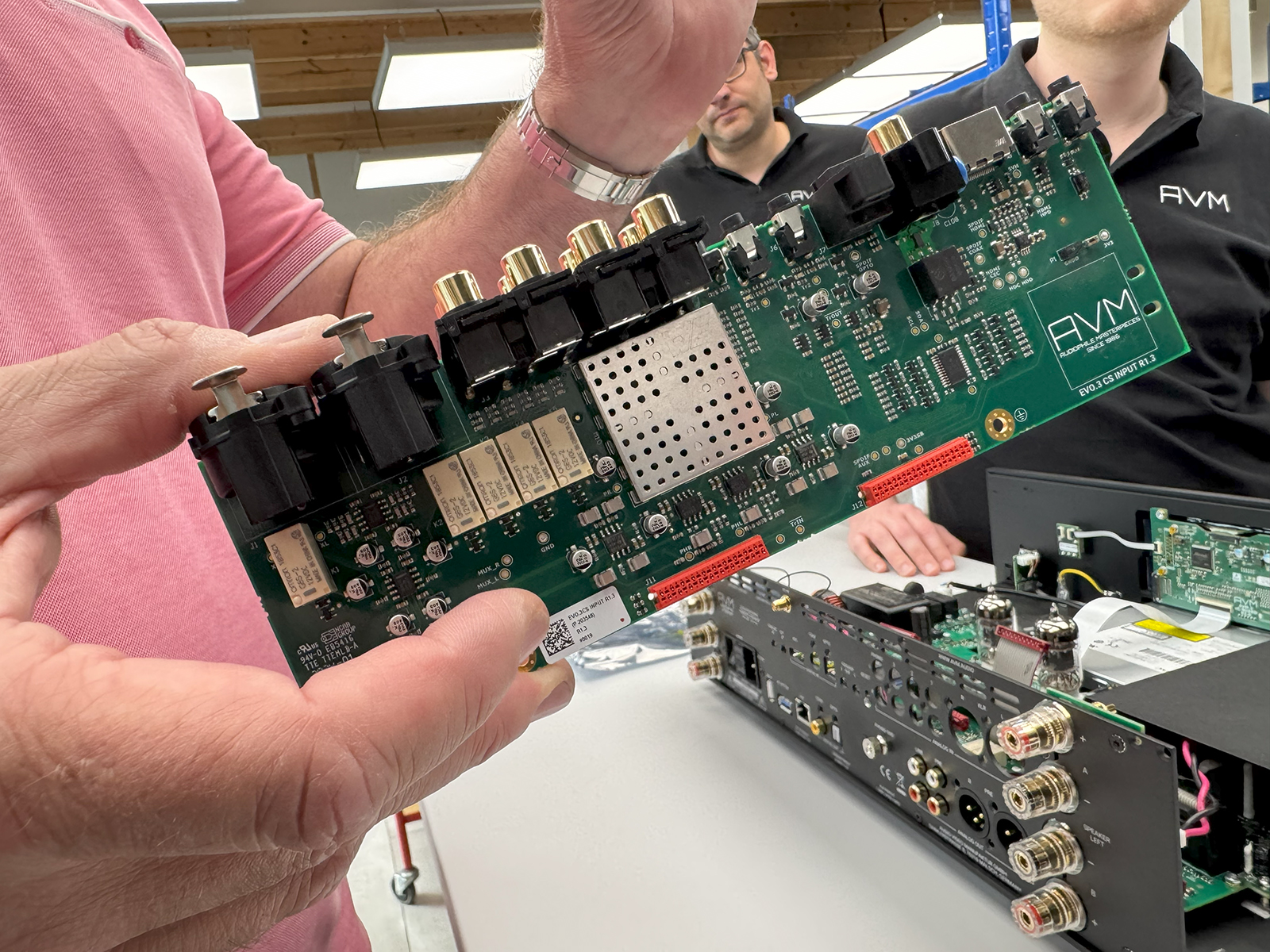

We got to examine the quality of the internals of some of the components on the line. We were shown how, on some integrated amps, an owner can switch from a transistor input stage to a custom tube input stage (or vice versa) with the simple swap of a small board. The unit automatically senses the change during power up and reconfigures itself to operate appropriately.

The QC area checks and processes every component produced to make sure everything meets or exceeds spec. The huge AVM Ovation Power amp that was hooked up to a large bank of load resistors was not simply being burned in or stress tested according to Ekinc Ufuk (AVM’s GM and COO). He insisted that it needed to be tortured in order to make sure that it wouldn’t break before it would get the final sign-off for shipment.

Surface Mount Pick and Place Machine.

Surface Mount Pick and Place Machine.

The rest of the visit included a stop at the facility that produces the circuit boards and populates the surface-mounted components (SMC) onto them. The attention to detail here was no less than that at the assembly area, with rigorous QC of every board being implemented.

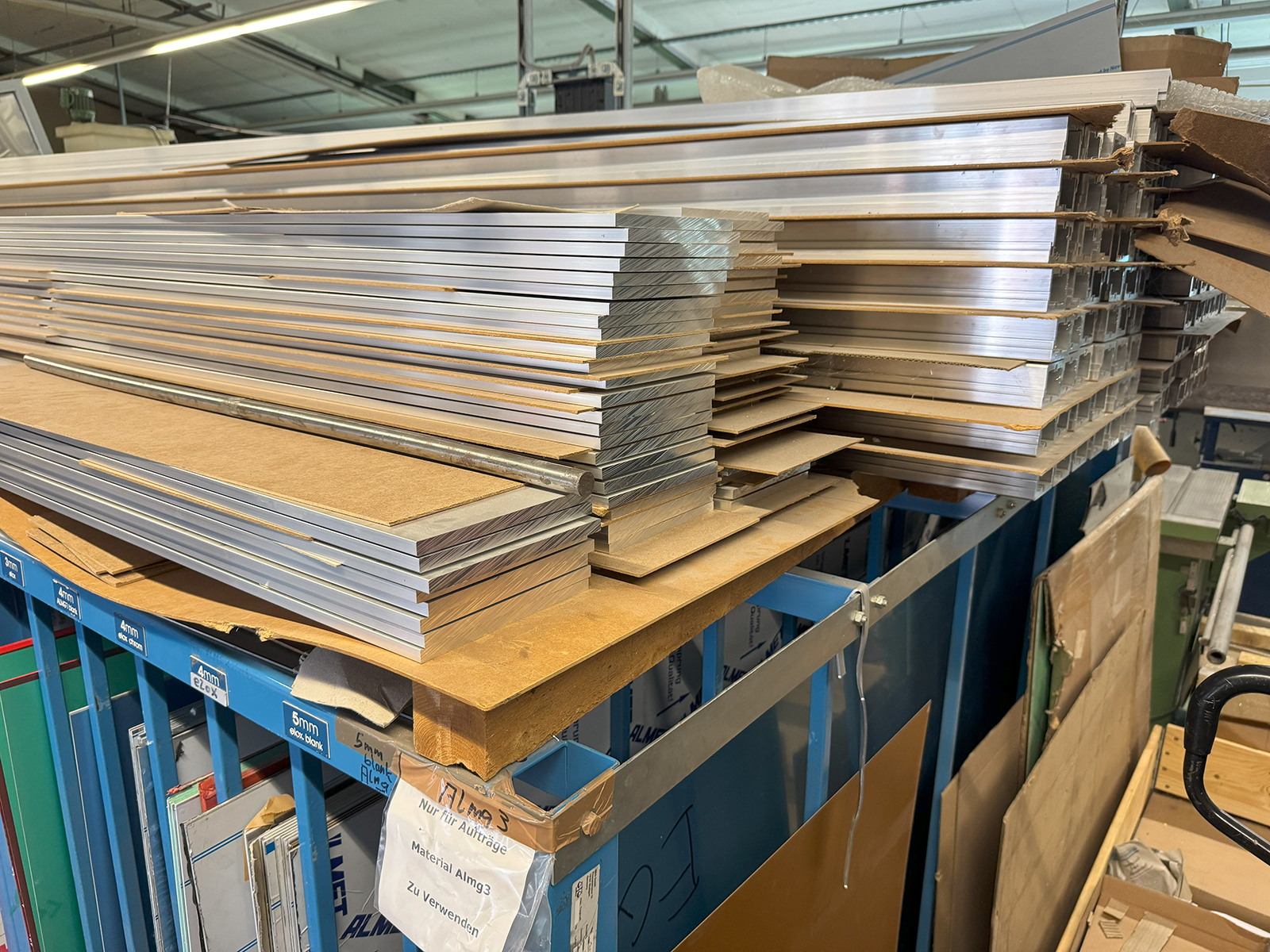

And we also visited the metalworking facility that does all the aluminum millwork for AVM’s components. This is a rawer, more earthy place with stacks of raw aluminum billet waiting to be cut, milled, and polished into their final forms. The fact that it was a real hands-on machine shop, as opposed to a whole big, automated CNC facility, was comforting and approachable.

AVM provides a select number of finishes on their component, but they have been known to offer some custom finish options like the Rust look you see here. Yes, that is a real developed rust that has been sealed to prevent additional decay or flaking. No Tetanus shot required!

We ended our time with AVM by visiting a local audio-video dealer, SG Acoustic, at their Villa Shellback location. This impressive, grand old German villa had been repurposed as a dealer experience center for AVM, VIABLUE, and other brands like FOCAL and Canton.

We all got to experience an assortment of gear in a variety of rooms in an essentially idyllic setting. It was a very fine way to close out a visit to Germany. Good music, good gear, and very, very good people connecting it all together.

Secrets Sponsor

Now…time to get one more helping of schnitzel, and a fine lager before the long flight home. Maybe even a little streusel…

We’d like to thank VIABLUE, AVM, and Fidelity Imports for the hospitality and the opportunity to dig a little deeper into these two great companies.