Nordost Heimdall Analog Audio Interconnects and Speaker Cables Part I April, 2006 John E. Johnson, Jr.

Introduction

I have told this story before, but just in case you have not heard it, Nordost is, in part, responsible for Secrets magazine being launched.

It was way back in 1993, when I attended one of my first CES conventions in Las Vegas.

This was before I ever considered publishing a hi-fi magazine.

At the convention center, I met Vincent Garino, who was manning the Nordost booth. At that time, their only product was Flatline, which was a simple flat conductor speaker cable, using Teflon as the dielectric.

I obtained a roll of it, since I needed to put the cable under the rug. My wife had been after me to take the cables off the nails in the ceiling molding. Those cables were too thick to put under the rug, so when I saw the Flatline, I knew I had the problem solved.

What I found was that the Flatline made a difference in the sound. That really surprised me. How could simple speaker cables do that?

Well, the cables were not that simple, as their flat conductors and Teflon insulation were there for a purpose.

I suddenly realized there were lots and lots of things about audio I did not know would make so much difference. When I found out why they made a difference, I though I might as well tell everybody else, and Secrets was born.

Anyway, that was back in the days when "Cables" were just emerging as an actual component in audio systems.

Since then, Nordost has prospered. Their technology, which they had designed for military use, now has expanded to include low-loss mono-filaments that are used in heart pace makers. And oh yes, audio and video systems as well.

I have used Nordost products now for more than a decade, and have always been very pleased with the performance.

At present, Nordost Valhalla is

their top of the line interconnect and speaker cable technology. It uses

silver-on-copper extruded conductors, and each conductor is wrapped with a

mono-filament in a helix. The helix separates the conductor from the Teflon

which surrounds it, so you end up with a dielectric constant somewhere in

between air and Teflon. The lower the dielectric constant, the better, for

this lowers capacitance.

Heimdall

The only problem with Valhalla is that it is

very, very expensive to manufacture. Since everything is extruded, the

chances of having a defect in one of the conductors is high. So, the discard

rate is high. And, so, the ultimate cost to the consumer is high. Mucho

high, in fact.

Nordost can't keep Valhalla products on the shelf. They make them as fast as possible, but it's not enough. So, it is not like they aren't selling all the products they make. However, not everyone an afford these things.

So, Nordost has trickled the technology down to some new models, including Heimdall, which is reviewed here. Other models include Tyr and Frey.

The difference between Valhalla and the other models that have the micro-filament technology is the number of conductors. While Valhalla speaker cable has forty conductors, Heimdall has twenty-four (twelve per leg in the speaker cables, 24 gauge). Frey has twenty-eight, 24 gauge, and Tyr has twenty, 20 gauge.

So, I decided to try out the Heimdall interconnects and speaker cables.

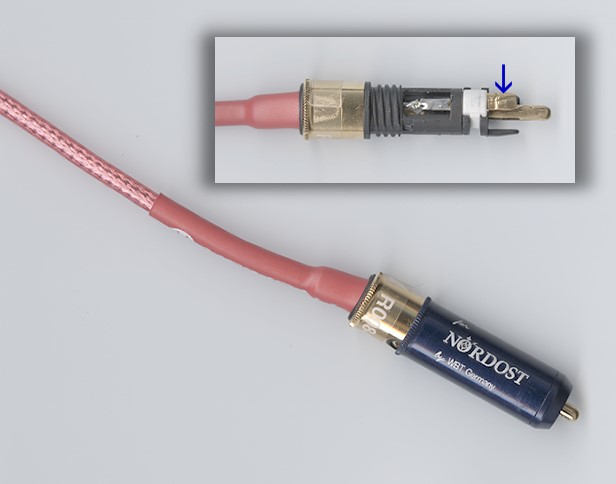

Below is a close-up photo of the Heimdall interconnects.

Besides the cool mono-filament technology, the Heimdalls use the new WBT RCA connector that has a single contact for the ground, pointed out by the arrow. This differs from conventional RCA plugs, where the contacts go all the way around the perimeter. This reduces eddy currents. Eddy currents are circular currents that can waste energy. By using the single contact, eddys are reduced.