Paradigm Audio – Prestige Series Facility and Manufacturing Tour, November, 2014

If I ever had to describe Canada’s most significant trait, I’d say it is modesty. Not in the bashful or apologetic kind of way, but rather in the quiet, proud confident way. In fact, Paradigm’s new moniker is “Crafted in Canada” instead of the more boastful, “Made in Canada” (or North America). Canadian modesty precludes boasting about an accomplishment; they’d rather show you than tell you. That’s what comes to mind when I look at the new Prestige speaker line and the impressive home of Paradigm in Mississauga, a neighboring city to the metropolis of Toronto, Ontario. It was a treat to tour the facility, watch the process of design, fabrication, and assembly of the Prestige Series.

Paradigm’s Studio Series has to be considered one of the most successful and highly rated speaker lines of all time, from any manufacturer. Surprisingly Paradigm just didn’t see advancing it to yet another version, v6. Instead, they began planning, researching, conducting interviews and round table discussions well over a year ago. Thus the concept of the Prestige series was a true collaboration.

The Prestige Series is complete with several floorstanding models in the 95F, 85F and 75F, two center channels in the 55C and 45C, a surround in the 25S and a bookshelf in the 15B. Two additional subwoofers still under development in the 1000SW and the 2000SW.

The obvious departure from the sculptural Studio, the Prestige returns to a simpler format, straight up rectangular. More of the discussion about the design and technology of the new line will follow in a future review. As I write this a pair of 85F’s are on their way. But this write-up is more about the facility in which Paradigm makes the Prestige inside and out, chassis, drivers, crossovers, assembles and tests.

The facility I’m told is more than 225,000 sq ft, that’s almost 5 acres. The facility also fabricates not only some of the other Paradigm series but also some of the Martin Logan electrostatic speakers. There is an air of casualness. People work in groups or individually but never as an assembly line. To say the least, it’s a very impressive operation.

Paradigm’s Brian Smith, Eastern Regional Sales Manager and National Sales Manager Rob Armstrong hold in-place the panels stacked and ready to assemble.

The panels locking edge groove is cut at either a CNC machine or cut with saws and the assigned angles.

The continuous locking joint insures a better square edge.

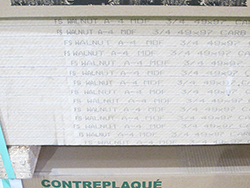

Not only is the unit manufactured in Canada but the raw good are also Canadian, the enclosure’s veneered sheet is fabricated in Quebec.

Once the chassis is built, it has the port’s and driver’s openings milled out.

The 15B enclosure ready for finish.

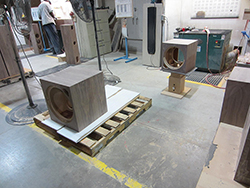

The subwoofer bodies, both sizes shown.

Note the front mounted control opening in the upper right corner.

The process of creating piano black finish requires buffing between layers of paint.

Unlike the glossy black finish which comes from multiple layers of painting and sanding, the veneer finish gets sanded and prepared for stain.

Shown are the variety of finish choices, ready for final.

Paradigm’s patent ART or Active Ridge Technology surrounds made in house offer greater excursion, up to 3dB.

The thermoplastic elastomer ART with the aluminum cone attached.

A 3D printer produces prototype for design to review.

The driver basket from a CAD file.

The suspension and voice coil assembly.

The crossover is mounted to the same plate holding the binding posts.

Not sure why anyone would cover these beautiful drivers, but the fabric frame is injection molded.

Marketing and Communications Manager Erin Phillips holding a completed screen held in place with magnets.

The drivers have a beautiful aluminum trim ring.

Paradigm is one of the very few anywhere, to have an exclusive full anechoic chamber.

The speaker, in this case a full rang 85F actually can mechanically spin allowing a variety of off-axis testing.

Ready to ship, 3-85F’s!

X-PAL tweeter with the tweeter lens cover.

Completed and a simply classic speaker look.

The aluminum “theme” carried through to the bi-amped binding posts.

The machined aluminum outriggers give a presence to the speaker.